You take care of your business, we take care of you

To grow in today's market, focusing on the core business is essential.

Our Logistics division is designed for this, to offer a wide range of on-demand solutions calibrated to the specific B2B or B2C product sector.

To free up resources and multiply opportunities.

10 plants

of over 300.000 square metres

cut-off times

easy and advantageous

Independence

in stock management

Manage your stock in our warehouses completely independently

All-round logistics

-

Space for performance

- Coverage of the most important import and distribution lines thanks to the locations of branches throughout the country

- Flexible and advantageous cut-off times thanks to the adjacence to BRT transport branches

- Maximum ability to reduce the time between inbound and outbound goods

- Possibility to customize services for each type of goods and for every need

- Capacity to adapt the operations and the shelf structure according to the type of goods

- Autonomous management of goods in the warehouse

-

Technological soul

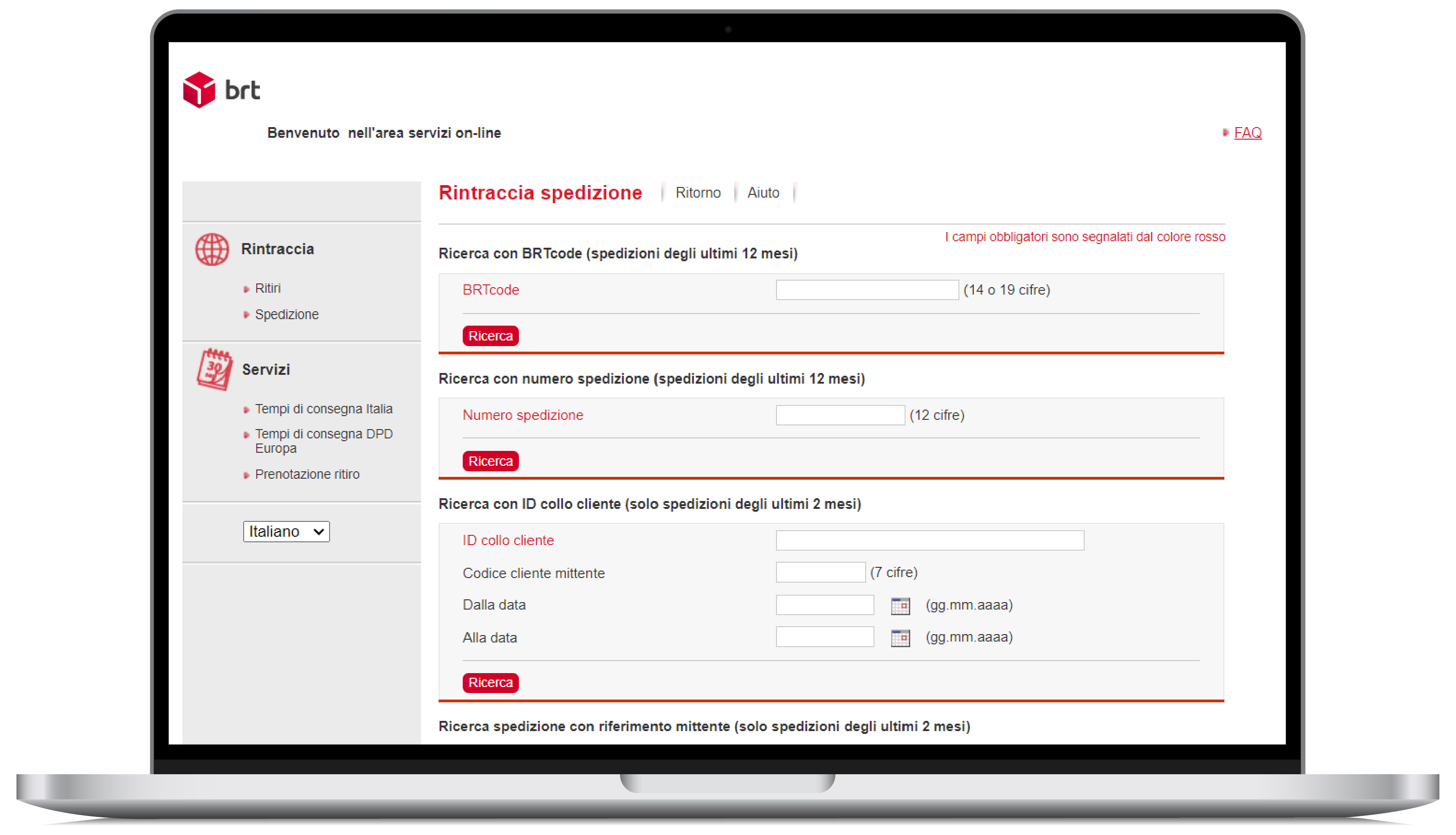

Behind every BRT logistics project there is an evolved technological structure: from the complete integration with the company's IT systems to the real time visibility of the processes for autonomous management, up to the monitoring and reporting activities built around customer's needs. -

Secure and protected

All goods, covered by an insurance policy, are stored in state-of-the-art facilities equipped with the most advanced 24/7 surveillance systems with anti-robbery, anti-intrusion and fire prevention devices.

All-round logistics

Space for performance

- Coverage of the most important import and distribution lines thanks to the locations of branches throughout the country

- Flexible and advantageous cut-off times thanks to the adjacence to BRT transport branches

- Maximum ability to reduce the time between inbound and outbound goods

- Possibility to customize services for each type of goods and for every need

- Capacity to adapt the operations and the shelf structure according to the type of goods

- Autonomous management of goods in the warehouse

Technological soul

Behind every BRT logistics project there is an evolved technological structure: from the complete integration with the company's IT systems to the real time visibility of the processes for autonomous management, up to the monitoring and reporting activities built around customer's needs.

Secure and protected

All goods, covered by an insurance policy, are stored in state-of-the-art facilities equipped with the most advanced 24/7 surveillance systems with anti-robbery, anti-intrusion and fire prevention devices.

Discover BRT solutions for Logistics

Do you want to discover more about BRT Logistics?

Home / Logistics